[inspection:print_pdf]

Plant Hazard and Risk Assessment

OWNER/INSPECTION DETAILS

Inspection #[inspection:inspection_number]

| Date | [inspection:inspection_date] |

| Provided for | [inspection:provided_for] |

| Plant Make & Model | [inspection:vehicle_year] [inspection:vehicle_make] [inspection:vehicle_model] |

| Identification No.s | [inspection:vehicle_registration] |

| Hour Meter Reading | [inspection:hours_reading] |

| Inspection Done at | [inspection:inspection_locale] |

Steersafe Training and Assessment ABN 84 137 032 681

Scott Haynes

Certificate IV Training & Assessment TAA40104

Certificate No 1678

Phone: 0418 536 870

[inspection:page_break]

CONTENTS

| OWNER DETAILS | 1 |

| ACKNOWLEDGMENT AND AGREEMENT | 3 |

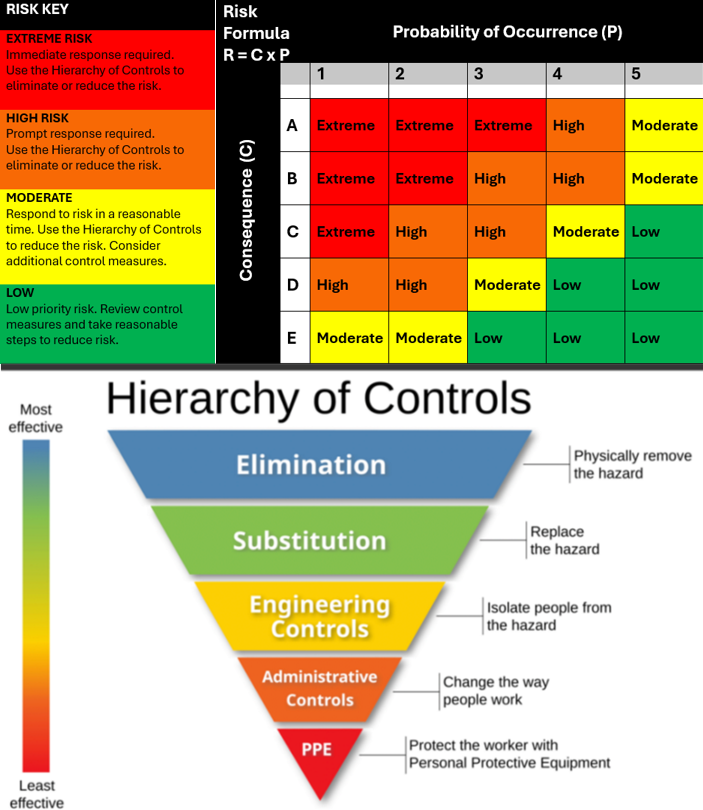

| RISK MATRIX & HIERARCHY OF CONTROLS | 4 |

| PLANT HAZARD & RISK ASSESSMENT | 5 |

| NOISE ASSESSMENT | 12 |

| OPERATOR ACKNOWLEDGEMENT | 13 |

| DISCLAIMER | 14 |

[inspection:page_break]

AGREEMENT

THIS AGREEMENT is made on [inspection:inspection_date_agreement]

and is made between:

SCOTT HAYNES of Steersafe Training and Assessment, and

[inspection:customer_representative] of [inspection:provided_for]

The owner/operator agrees to engage Scott Haynes to perform Risk Assessment on the basis of agreement to the following disclaimer.

DISCLAIMER

"Mobile Plant" means the mobile plant, vehicle or equipment described in the assessment and inspected by the assessor.

This assessment is based upon information provided to the assessor up until the date of the assessment. If any modification, alteration or addition is made to the mobile plant following that date, this asessment is null and void and cannot be relied upon for any purpose. In particular, this assessment will then provide no assurance that the mobile plant complies with the Occupational Health and Safety Regulations 2017 or any regulation amending or replacing those regulations. The owner and operator of the mobile plant must conduct regular inspections and maintain the mobile plant at regular intervals. If any alteration or addition is made to the mobile plant, such alterations or additions must be recorded in writing and retained by the owner and operator. The mobile plant will then need to be re-assessed.

At all times it is the responsibility of the owner and operator of the mobile plant to maintain the mobile plant according to the Occupational Health and Safety Regulations 2017 and all other applicable legislation and regulations. The assessor is not and shall not be liable for the mobile plant complying with the Occupational Health and Safety Regulations 2017 or any regulation amending or replacing those regulations. This assessment does not pass any responsibility for such compliance to the assessor, and does not in any way exempt the owner and operator from the continuing responsibility for such compliance. The owner and operator agree to indemnify the assessor against all liability of whatever kind in relation to the mobile plant assessed.

This assessment will be conducted by a qualified workplace assessor. This assessment will not be conducted by a qualified mechanic nor a roadworthy assessor, and no responsibility is assumed by the assessor for any mechanical malfunction of the mobile plant nor lack of roadworthiness.

This assessment identifies risks in relation to the mobile plant only, and does not assess risks in relation to the site where the mobile plant is to be used. A job safety and environmental analysis is required to identify such site risks and should be reviewed by the owner and operator prior to commencement of work on site.

ACKNOWLEDGEMENT AND AGREEMENT

I confirm that I have read and understood the disclaimer and notes set out about and agree with all terms

| Name: [inspection:customer_representative] Company/Organization: [inspection:provided_for] | Signed: | [inspection:customer_signature] | |

| Date: [inspection:inspection_date] |

[inspection:page_break]

RISK MATRIX

[inspection:page_break]

PLANT HAZARD & RISK ASSESSMENT

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) material falling off the plant | H I G H | Operator licensed to operate plant | [inspection:licence_valid] | [inspection:licence_valid_issues] | M E D I U M |

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| (b) uncontrolled or unexpected movement of the plant or its load | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | ||

| Horn fitted | [inspection:horn] | [inspection:horn_issues] | |||

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| Reverse swing/ warning lights | [inspection:reverse_swing] | [inspection:reverse_swing_issues] | |||

| Flashing beacon | [inspection:flashing_beacon] | [inspection:flashing_beacon_issues] | |||

| Non slip pedals | [inspection:nonslip_pedals] | [inspection:nonslip_pedals_issues] | |||

| Mirrors fitted | [inspection:mirrors] | [inspection:mirrors_issues] | |||

| Parking brake operational | [inspection:brakes] | [inspection:brakes_issues] | |||

| (c) difficulty in slowing, stopping or immobilising the plant | Service brake operational* | [inspection:service_brake] | [inspection:service_brake_issues] | ||

| Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | |||

| (d) the plant tipping or rolling over | ROPs approved structure or cabin | [inspection:rop_fitted] | [inspection:rop_fitted_issues] | ||

| ROPs sticker fitted | [inspection:rop_stickers] | [inspection:rop_stickers_issues] | |||

| (e) being thrown off or under the plant | Doors fitted | [inspection:doors] | [inspection:doors_issues] | ||

| ROPs approved structure or cabin | [inspection:rop_fitted] | [inspection:rop_fitted_issues] | |||

| Seat belt fitted | [inspection:seatbelt] | [inspection:seatbelt_issues] | |||

| Cabin fully enclosed | [inspection:cabin_enclosed] | [inspection:cabin_enclosed_issues] | |||

*Brakes are checked for function, and not for brake adjustment or brake wear. This is solely the responsibility of the owner/operator.

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| (f) being trapped between the plant, materials or a fixed structure. | H I G H | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | M E D I U M |

| Neutral start switch | [inspection:neutral_start] | [inspection:neutral_start_issues] | |||

| Horn fitted | [inspection:horn] | [inspection:horn_issues] | |||

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| Flashing beacon | [inspection:flashing_beacon] | [inspection:flashing_beacon_issues] | |||

| Non slip pedals | [inspection:nonslip_pedals] | [inspection:nonslip_pedals_issues] | |||

| Mirrors fitted | [inspection:mirrors] | [inspection:mirrors_issues] | |||

| (g) attachments. ie buckets, blades, drills, etc | Pins and bushes in good condition | [inspection:pins_bushes] | [inspection:pins_bushes_issues] | ||

| (h) any other factors not mentioned | [inspection:crushing_other] | [inspection:crushing_other_issues] | |||

| |||||

| (a) between two parts of the plant | H I G H | Decals fitted | [inspection:decals] | [inspection:decals_issues] | M E D I U M |

| Burst protection valves fitted where required | [inspection:burst_valves] | [inspection:burst_valves_issues] | |||

| (b) between a part of the plant and a work piece or structure | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | ||

| Swing lights fitted where required | [inspection:swing_lights] | [inspection:swing_lights_issues] | |||

| Horn fitted | [inspection:horn] | [inspection:horn_issues] | |||

| (c) any other factors not mentioned | [inspection:shearing_other] | [inspection:shearing_other_issues] | |||

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) uncontrolled or unexpected movement of the plant or material | M E D I U M | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | L O W |

| Reversing warning decal fitted | [inspection:reverse_decal] | [inspection:reverse_decal_issues] | |||

| Flashing beacon on plant | [inspection:flashing_beacon] | [inspection:flashing_beacon_issues] | |||

| Horn fitted | [inspection:horn] | [inspection:horn_issues] | |||

| Controls/levers identified | [inspection:controls_levers] | [inspection:controls_levers_issues] | |||

| (b) the plant, or parts of the plant disintegrating | Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | ||

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| Guards fitted as required | [inspection:striking_guards] | [inspection:striking_guards_issues] | |||

| (c) the mobility of the plant | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | ||

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| Flashing beacon | [inspection:flashing_beacon] | [inspection:flashing_beacon_issues] | |||

| (d) any other factors not mentioned | [inspection:striking_other] | [inspection:striking_other_issues] | |||

| |||||

| (a) hair, clothing or any other items they are wearing or attached to them, become entangled in the moving parts of the plant or materials on the plant? | M E D I U M | Guards fitted as required | [inspection:entanglement_guards] | [inspection:entanglement_guards_issues] | L O W |

| Warning decals for moving parts | [inspection:entanglement_decals] | [inspection:entanglement_decals_issues] | |||

| (b) any other factors not mentioned | [inspection:entanglement_other] | [inspection:entanglement_other_issues] | |||

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) contact with sharp or moving parts on the plant | M E D I U M | Guards fitted as required | [inspection:cutting_guards] | [inspection:cutting_guards_issues] | L O W |

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| (b) the plant, or parts of the plant disintegrating | Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | ||

| (c) uncontrolled or unexpected movement of the plant or material | Reverse alarm fitted | [inspection:reverse] | [inspection:reverse_issues] | ||

| Reversing warning decal fitted | [inspection:reverse_decal] | [inspection:reverse_decal_issues] | |||

| Flashing beacon | [inspection:flashing_beacon] | [inspection:flashing_beacon_issues] | |||

| Horn fitted | [inspection:horn] | [inspection:horn_issues] | |||

| Brake lights and indicators | [inspection:brake_lights] | [inspection:brake_lights_issues] | |||

| Rear swing/reverse warning lights | [inspection:reverse_swing] | [inspection:reverse_swing_issues] | |||

| (d) any other factors not mentioned | [inspection:cutting_other] | [inspection:cutting_other_issues] | |||

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) slippery or uneven work surfaces | M E D I U M | Non slip steps and work area | [inspection:nonslip_work_area] | [inspection:nonslip_work_area_issues] | L O W |

| (b) inadequate steps and handrail to enter and exit plant | Non slip steps and handrail to ensure 3 points of contact to enter and exit plant | [inspection:nonslip_vehicle] | [inspection:nonslip_vehicle_issues] | ||

| (c) inadequate rail or other suitable edge protection | Handrail or edge protection in place where required | [inspection:handrail_edge] | [inspection:handrail_edge_issues] | ||

| (d) obstacles in the vicinity of the plant. E.g.: oil spill or plant attachments | No visible signs of fluids leaking from plant | [inspection:no_visible_fluids] | [inspection:no_visible_fluids_issues] | ||

| Work area free from debris and work materials | [inspection:work_area] | [inspection:work_area_issues] | |||

| (d) any other factors not mentioned | [inspection:tripping_other] | [inspection:tripping_other_issues] | |||

| |||||

| (a) badly designed or damaged seating | M E D I U M | Driving seat in good condition | [inspection:seat_condition] | [inspection:seat_condition_issues] | L O W |

| (b) inhibited body posture or the need for excessive effort | Adjustable seat position | [inspection:seat_adjustable] | [inspection:seat_adjustable_issues] | ||

| Adjustable driving controls | [inspection:controls_adjustable] | [inspection:controls_adjustable_issues] | |||

| (c) inadequate lighting | Adequate lights in and outside of cabin | [inspection:lights] | [inspection:lights_issues] | ||

| (d) unsafe entry and exit points | Non slip steps and handrail to ensure 3 points of contact to enter and exit plant | [inspection:nonslip_vehicle] | [inspection:nonslip_vehicle_issues] | ||

| (e) any other factors not mentioned | [inspection:ergonomic_other] | [inspection:ergonomic_other_issues] | |||

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) exposed and damaged battery or leads | M E D I U M | Guards around battery or wiring | [inspection:electrical_guards] | [inspection:electrical_guards_issues] | L O W |

| Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | |||

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| (b) the plant contacting live electrical conductors | JSAs on site and spotters when operating near overhead wires | [inspection:jsa_spotters] | [inspection:jsa_spotters_issues] | ||

| (c) damaged electrical wiring, switches or cables | Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | ||

| (d) any other factors not mentioned | [inspection:electrical_other] | [inspection:electrical_other_issues] | |||

| |||||

| (a) contact with exhaust | M E D I U M | Guards around exhaust | [inspection:exhaust_guards] | [inspection:exhaust_guards_issues] | L O W |

| Decals fitted | [inspection:decals] | [inspection:decals_issues] | |||

| Exhaust mounted away from easy access | [inspection:exhaust_inaccessible] | [inspection:exhaust_inaccessible_issues] | |||

| (b) fire in the plant | Regular maintenance of plant as recorded | [inspection:service_maintenance_records] | [inspection:service_maintenance_records_issues] | ||

| Fire extinguisher supplied in plant | [inspection:fire_extinguisher] | [inspection:fire_extinguisher_issues] | |||

| (c) any other factors not mentioned | [inspection:burns_other] | [inspection:burns_other_issues] | |||

| |||||

| (a) high pressure fluid | M E D I U M | Regular maintenance of hydraulic hoses and couplings as recorded | [inspection:hydraulic_maintenance] | [inspection:hydraulic_maintenance_issues] | L O W |

| (b) explosions caused by gas, vapours, liquids or other substances | All seals and tanks in good working order | [inspection:seals] | [inspection:seals_issues] | ||

| (c) any other factors not mentioned | [inspection:pressure_other] | [inspection:pressure_other_issues] | |||

[inspection:page_break]

| Hazard | Initial Risk | Control | Control in place | Action Required | Residual Risk |

|---|---|---|---|---|---|

| |||||

| (a) lack of oxygen within the plant cabin | M E D I U M | Adequate ventilation (windows) | [inspection:ventilation] | [inspection:ventilation_issues] | L O W |

| Air conditioning | [inspection:aircon] | [inspection:aircon_issues] | |||

| (b) fumes, toxic gases or vapours within the plant cabin | Exhaust in good operating condition | [inspection:exhaust_condition] | [inspection:exhaust_condition_issues] | ||

| (c) dust within the plant cabin | Door and window seals in good condition | [inspection:door_condition] | [inspection:door_condition_issues] | ||

| (d) overheating within the plant cabin | Adequate ventilation (windows) | [inspection:ventilation] | [inspection:ventilation_issues] | ||

| Air conditioning | [inspection:aircon] | [inspection:aircon_issues] | |||

| (e) any other factors not mentioned | [inspection:suffocation_other] | [inspection:suffocation_other_issues] | |||

| |||||

| (a) excessive noise | M E D I U M | Hearing protection supplied N.B. See noise level test for more detail | [inspection:hearing_protection] | [inspection:hearing_protection_issues] | L O W |

| (b) vibration | Excessive Vibration | [inspection:vibration] | [inspection:vibration_issues] | ||

| (c) excessive temperatures in cabin | Heater and air conditioner | [inspection:heater] | [inspection:heater_issues] | ||

| Adequate ventilation and sealing doors and windows | [inspection:ventilation] | [inspection:ventilation_issues] | |||

| (d) any other factors not mentioned | [inspection:misc_other] | [inspection:misc_other_issues] | |||

| |||||

| (a) daily pre start inspection check list | M E D I U M | Pre start provide | [inspection:daily_check_list] | [inspection:daily_check_list_issues] | L O W |

| (b) service and maintenance records | Service history provided | [inspection:maintenance_records] | [inspection:maintenance_records_issues] | ||

| (c) plant operation manual | Plant Manual provided | [inspection:operators_manual] | [inspection:operators_manual_issues] | ||

| (d) suitable licence for operation of the plant | Licence provided | [inspection:licence_valid] | [inspection:licence_valid_issues] | ||

NOTE

High risk denotes a possible or probable occurrence and possible death, or life threatening injury, or permanent disability without the use of controls.

Medium risk denotes unlikely or possible occurrence and possible injury without the use of controls. [inspection:page_break]

NOISE ASSESSMENT

The noise level reading shall be taken at exhaust level, and within 1050mm of the exhaust emission. The reading will be taken at idle and at “Engine Speed at Maximum Power”. This procedure is in accordance with the Environment Protection (Vehicle Emissions) Regulations 2003.

A further reading shall then be taken from the cabin of the Plant.

The sound meter used for this assessment is a Digitech QM-1589, Serial No 10060748 in accordance with the Environment Protection (Vehicle Emissions) Regulations 2003.

| Plant Details | [inspection:vehicle_year] [inspection:vehicle_make] [inspection:vehicle_model] |

| Identification No. | [inspection:vehicle_registration] |

| Background Noise | [inspection:background_noise] |

| Noise in Cabin at Idle | [inspection:cabin_idle] |

| Noise in Cabin at Maximum Power | [inspection:cabin_power] |

| Noise at Idle | [inspection:noise_idle] |

| Noise at Maximum Power | [inspection:noise_power] |

[inspection:page_break]

OPERATOR ACKNOWLEDGMENT

Operator to read this risk assessment report and complete and sign below.

I have read and understood this risk assessment report and confirm that I hold the required qualifications to operate the assessed Plant equipment.

| Operator Full Name | Operator Qualification | Operator Signature | Date Signed |

| |||

| |||

| |||

| |||

| |||

| |||

| |||

| |||

| |||

| |||

|

[inspection:page_break]

DISCLAIMER

“Mobile Plant” means the mobile plant, vehicle or equipment described in the assessment and inspected by the assessor.

This assessment is based upon information provided to the assessor up until the date of the assessment. If any modification, alteration or addition is made to the mobile plant following that date, this assessment is null and void and cannot be relied upon for any purpose. In particular, this assessment will then provide no assurance that the mobile plant complies with the Occupational Health and Safety Regulations 2017 or any regulation amending or replacing those regulations. The owner and operator of the mobile plant must conduct regular inspections and maintain the mobile plant at regular intervals. If any alteration or addition is made to the mobile plant, such alterations or additions must be recorded in writing and retained by the owner and operator. The mobile plant will then need to be re-assessed.

At all times it is the responsibility of the owner and operator of the mobile plant to maintain the mobile plant according to the Occupational Health and Safety Regulations 2017 and all other applicable legislation and regulations. The assessor is not and shall not be liable for the mobile plant complying with the Occupational Health and Safety Regulations 2017 or any regulation amending or replacing those regulations. This assessment does not pass any responsibility for such compliance to the assessor, and does not in any way exempt the owner and operator from the continuing responsibility for such compliance. The owner and operator agree to indemnify the assessor against all liability of whatever kind in relation to the mobile plant assessed.

This assessment has been conducted by a qualified workplace assessor. This assessment was not conducted by a qualified mechanic nor a roadworthy assessor, and no responsibility is assumed by the assessor for any mechanical malfunction of the mobile plant nor lack of roadworthiness.

This assessment identifies risks in relation to the mobile plant only, and does not assess risks in relation to the site where the mobile plant is to be used. A job safety and environmental analysis is required to identify such site risks and should be reviewed by the owner and operator prior to commencement of work on site.

ACKNOWLEDGMENT AND ACCEPTANCE

I confirm that I have read and understood the disclaimer and notes set out above and agree with all terms.

I also acknowledge I have received the completed Risk Assessment for the aforementioned Mobile Plant

| Name: | [inspection:customer_representative] | Company/Organisation: [inspection:provided_for] | |

| Signed: | [inspection:customer_signature] | Date: [inspection:inspection_date] | |